How to Wire SIPs

December 1, 2006You’re going to take the leap and build a SIPs house. Everything is set; manufacturer, dealer, designer. Even your architect thinks it’s a good idea after you agree to supply him with a month’s worth of espresso.

You were lucky and lined up the subs ahead of time. The roofing, siding, flooring, and concrete contractors all said they had been looking for the opportunity to work with SIPs. Even better, your HVAC guy has already cut his teeth on three SIP structures and is fully on board.

Now all you have to do is line up an electrician.

A big question with SIPs is how do you make the electrical connection? Unfortunately for you, the SIP industry has a bad wrap when is comes to running wire. Is this reputation deserved? If the electrician shows up on the job without a good understanding of wiring panels and/or the installers don’t help him out by communicating with him, the job is going to be a nightmare and that electrician will blame it on SIPs instead of where the real blame belongs (frankly that’s you).

The general contractor is responsible for making sure the SIP installers and the electricians communicate so that the electrician knows what tools he’ll need and has the information to do the job well.

If you build a SIP house, it’s all on you. But luckily, prepping a SIP house doesn’t take much time if you make it part of the install. The tools you’ll need aren’t that expensive or hard to operate. And, if done right, the proper electrical prep, will save you tons of aggravation down the road.

Who’s smiling now?

Here’s how to do it.

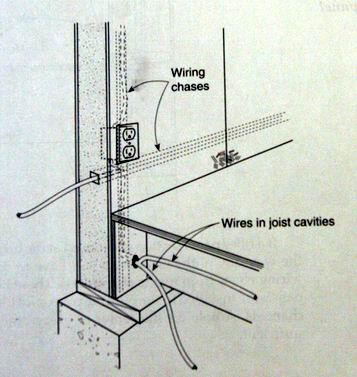

First, find out what your SIP manufacturer will do. Most have horizontal and vertical chases but they may also add chases for a nominal charge based on your design. This will save a bunch of time later on.

Second, become familiar with a few tricks that will make the installation a breeze.

The Hot Ball

Buy a ball bearing from a local machine shop. EPS panels will turn to vapor under very high temperatures.

Heat up a the ball with a torch. You want the color to be just under red. At this temp the ball will move through the foam but not cause a flame.

Drop it in the hole and watch it disappear.

Create a funnel for it to escape.

Presto chase.

Don’t touch it!

Standard auger

For short distances, you can plunge holes with a big auger.

If you’re using this hog, hold on tight.

Flex bit

A flex bit is your biggest friend for long runs.

Clearly identify where you need to go and angle it in.

Bingo.

This connector hole can be filled later.

Crane time

The rest of the flipbook

Now it’s time for some real fun.

R&R

Our local building codes require all electrical run through metal conduit.

How is this possible with Sips?

That’s a good question. If it’s flexible conduit (which I’m almost sure would be allowed for a residential structure) you could push and pull it the same way that you would a wire. Most of the wiring in a SIP house can happen in the floor system and so whether it’s metal conduit or not might not make that much difference.

By the way — sorry for the delayed response. I was at the World Of Concrete Expo in Las Vegas.

roofing contractor

roofing contractor

I have a big question about mounting electrical boxes. After looking at several of the SIPS manufacturer sites, while they have electrical chases to fish the wiring through, most say “mount the box to the outside of the panel.” WHAT? Seems both ugly and Micky Mouse. The steel SIPS panels ask you to frame up an additional inside dead wall space. Instead wouldn’t you route the box site recessed into the panel, set it, and backfill gaps with foam? Are there specific tools for this or do you just use a rotozip? And does anyone know a contractor willing to even TRY SIPS in North Louisiana?

we do steel sips in Louisiana and SE US

im planning to wire my fathers timber frame home in the summer this year. i too wondered how the boxes would be fastened in place and this is the best solution ive come up with. the use of face nailer or remodeler cut-in boxes should work great. the face nailer box has a slim steel bracket of one side of the box and can be nailed straight the the OSB. if you fear the bracket affecting the drywall application, the cut in box could work just as well. cut-in boxes have little wings or tabs which swing out and grab the interior sheeting surface. after the box hole is cut use a razor knife to trim the foam 3/4′ all the way around the box hole. this allows the wings to grab the OSB and voila! hope that helps

You could try an alternative panel core such as polyurethane SIP that has the electrical and conduit built into the panel. It’s pretty sweet I have to admit and no mess no fuss no burning ball or routing or “snow” the ground.

Nice Blog. Thanks for sharing with people who were unfamiliar before.

fur out the wall to create a wire chase the use hard pipe

Although electricity is used in every aspect of our lives, it is very dangerous for you to mess with if you haven’t been formally trained and educated. Whenever you have electrical problems, hire an electrician right away http://www.roslynlimo.com/ are the best in this field.

the whole thing sounds mickey mouse to me, first of all instead of heating a ball and dropping it in I would just grind the end of a piece of conduit and heat that and shove it through for a clean hole. but frankly it all looks like a poor though out set up. what about HVAC or vertical electric how are you going to line up the holes from one floor to another and go through the decking. that s just the start

Will the hot ball bearing trick work on that spray foam insulation ?

Not hardly. Polyurethane foam doesn’t melt so easy as that. SIPs with a polyurethane (the yellow spray foam) core have the conduit and electrical boxes inside the panels first and then the foam is injected around that. It’s tricky, which is why there are many more EPS Panel manufacturers that Polyurethane Panel manufacturers. And of course in my opinion a much better products. Everything is factory fabricated, which means very little, if any, cutting in the field. But if you had to cut chases into polyurethane foam panels, you would need a router.

Thanks Meredith. You were right. It didn’t melt (well it did but only when an inch at the most – and the ball was red hot).

So, had to spend $50 and get a 1″ flex drill bit and grind that stuff out.

So to all with spray foam insulation. It doesn’t work to hot ball. Just melts and scares you thinking you’re going to get a ball stuck in the wall.

Hey! This is my 1st comment here so I just wanted to

give a quick shout out and tell you I really enjoy reading through your blog posts.

Can you recommend any other blogs/websites/forums that cover the same topics?

Thank you!

http://www.sips.org orhttp:// www,sipweb.com

Hey! I know this is kinda off topic but I’d figured I’d ask.

Would you be interested in trading links or maybe

guest authoring a blog article or vice-versa?

My website addresses a lot of the same topics as yours and I think we could greatly benefit from each other.

If you’re interested feel free to send me an email.

I look forward to hearing from you! Wonderful blog by the way!